- GST No. 07AAFCG4939G1ZH

- Send SMS

- Send Email

Sports Ground Construction Services

Leading Manufacturers, Exporters, Wholesaler of Badminton Court Construction Services, Basketball Court Construction Services, Cricket Ground Construction Services and Tennis Court Construction Services from Delhi.

Made available by us are Badminton Court Construction for both commercial and non-commercial purposes. High grade material and latest equipment are employed in designing these courts. The spectrum of services offered by us have benefited many schools, colleges and sports complexes. We design both indoor and outdoor badminton courts.

Specifications :

Area :

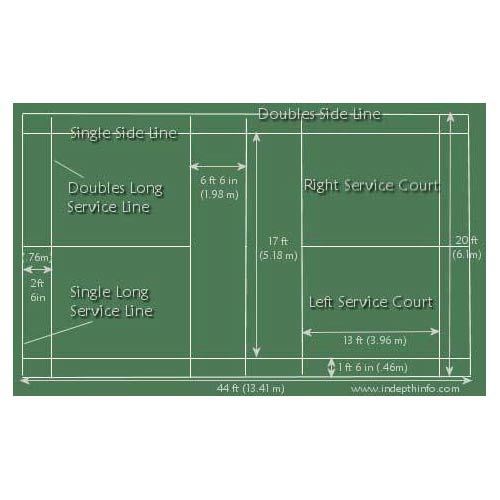

- Total area: 1620 square feet as recommended by the american badminton association

- Singles badminton court: 17’ x 44’

- Doubles badminton court: 20’ x 44’

- A minimum 5’ unhindered area on all sides of the court

Surface :

- Concrete or bituminous material as recommended for a badminton court

- A permanently installed court can be sheltered with a color coating

- Non slippery yet smooth and leveled

Net :

- Badminton net can be made of fine cord of dark color and even thickness

- Should have a mesh of minimum 15 mm and a maximum 20 mm

- The width of net must be at least 6. 1 meters

Softout : Softout of a sports court surface is made of rubber carpet and acryl coats. These materials produce the elasticity in the surface, which makes the court player friendly. They result in curtailing injury risks for those playing on the court. This surface is very low on maintenance and performs excellently in a wide range of extreme temperature (-50 to 120 degree celsius). Softout is suitable for all courts’ surfaces because of its flexible characteristics.

Surface Evolution : To reduce the risk of joint fracture and to provide the surface for easy movement we provide a double layer rubber grain pad. Protected with elastic synthetic resin evolution surface has no flint aggregates and also provides extreme durability and resistance to weather changes. It is appropriate for all types of sports courts.

Average material usage : 4. 0 g/m sq.

Colors : Green, red blue, violet and many more.

Synthetic grass : Swynthetic grass surface is highly recommended for multi -functional sports courts used in various holiday resorts and multi-purpose sports centers. Girdhari lal contractor is surface meets the customer is needs in terms of appearance and requirement. It provides high quality material for low price making it a profitable investment. Our surface is resistant to uv rays and extreme weather changes, as it has passed many performance tests.

We are a paramount designer of Basket Ball Court Construction across the nation. These courts are designed according to the requirements of our esteemed customers. The courts offered by us are highly appreciated for their premium quality, attractive colors, strength and resistance against change in weather. Clients can easily remove dust, dirt and stain from the floor of these courts. Also, we customize these as per the clients' detailed specifications.

Cricket is a not just a sport in india, it is treated as a religion and the supporters are the ones who make it so big. We have been involved in Cricket Ground Construction for 2 decades, and our profound experience has perfected us in this type of construction.

We use the highest grade raw materials of preparing cricket pitches which provide with the best bounce and movement of the ball on the pitch. This involves a labor intensive technique and we employ the best of manpower. With the changing demands, we have also mastered ourselves in offering oval cricket ground construction services in india. Involving a huge stadium viewer ship, cricket grounds built by us are well known for their comfortable seating arrangements. Preparing proper drainage system along with superb quality practice pitches are the part of our gamut of services.

Cricket Pitch Construction :

Owing to their own distinguished features cricket pitches and outfields are different. Girdhari lal contractor is rich experience in the construction and maintenance of cricket wickets and pitches is ensures expert planning and utmost care in every project. Special materials are required while constructing a cricket pitch. Special loam soils are used over clay to provide the precise level of bounce and movement off the pitch. This process is essential to maintain the ‘ball bounce’. We assure the best of services at the most affordable prices. We specialize in renovating cricket pitches and we utilize a wide range of our equipments to remove an old pitch, rebuild a new one and laser level to ensure a perfect playing surface for future years.

Binding Strength Test :

The naturally available top soil may need addition of one or other type of soil to make it good top soil. Fortunately in india vast variety of soils are available. One of sample top soil form village pamal, near ludhiana has the following properties :

- Coarse sand 5%,

- Ilt 50% and clay 45% (tested as per is 2720 part-4) liquid limit 44% plastic limit 28% and pi 16 (is 2720 part-5),

- linear shrinkage 11% (is 2720 part-20),

- free swell index 25% (is 2720 part-40) and strength (½” x 1” cylinder of soil converted into motty) 95 kg

Adding just 5 % of fine sand will makes a good top soil. Because of the poor laying, irrigation, compaction and maintenance techniques most of pitches prepared using this soil have become slow with time.

Pitch Construction : Suggestions for a correctly constructed pitch

- Careful assessment of the drainage: unless there is a treat of a developing a perched water table, a perimeter drain surrounding the table should be sufficient to drain surface water and reduce lateral uptake of water by the table if a plastic lining is not present.

- Avoid complicated (and unnecessary) combinations of a range of materials under the bulli. Medium crusher-run stone should be sufficient.

- Ensure the use of only finest grade clay, which has been analyzed and passed.

- Consult widely and make certain that each stage of construction has been carefully researched and planned. Do not allow a hurried operation to justify short cuts.

- Ensure adequate compaction occurs at every possible stage.

Construction Specifications :

- Base conditions and base layers: the most general is the use of medium crusher run stone

- Each material layer must be bonded or keyed to the layer below

- The clay should be of superior quality meeting the standard specifications

- Good compaction must be achieved at every level and sub-level

We undertake Tennis Court Construction to produce the best New Grass Court, Clay Court, Dehradun Bajiri Court, Synthetic Tennis Court, Tennis Court Side Net, Practice Wall, and Hard Court. The Courts prepared by us are in compliance with the set international standards of size and dimension. We are rated as a reliable Tennis Court Construction Company. The variety of our Court Surfaces is made using the best quality raw materials. We use the finest quality clay which is blended with green stone to give the lifelong surface. For the Synthetic Surface we use the finest synthetic grass fibers which are held in place by backing mat with finely graded sand. Beside, we are a leading name in the Tennis Court Surface Construction.

Tennis Court Construction Basics :

If you are considering a new tennis court, here are some basic requirements to consider.

Size and Space :

- A standard size tennis court for doubles play measures 60' x 120' from fence to fence. For batteries of two or more courts, a minimum of 48' additional width is allowed for each extra court. For example, two courts measure 108' x 120', three courts measure 156' x 120', etc.

- Total cleared space, however varies depending upon site topography, perimeter drainage needs, landscaping and so on. You will need a minimum of 5' around the entire court perimeter. A steeply sloped site requires more clearing to allow for natural sloping around the court. Additional space provisions are needed for special drains, elaborate landscaping or patios.

- Courts can be smaller than these dimensions, but since the playing lines for doubles are always 36' x 78', undersizing compromises safety and quality of play.

Orientation : If possible, a tennis court is situated in a true north-south direction.

Perimeter Sloping & Drainage : A court built into the side of a hill requires different perimeter sloping and drainage than one built on a flat, open area. To divert surface water from washing onto or under a court, a variety of techniques are used, ranging from natural swales, to elaborate underground systems. Sometimes retaining walls are required with drainage provisions behind the walls. This all affects size and space requirements.

Fencing : Lots of options here. A standard fence is 10' high, but 8' or 12' may be appropriate at times. The court can be fully enclosed with a high fence or sides can be left open or enclosed with a lower 3' or 4' fence. Corners can be a traditional 90 degrees or cut off diagonally. Support systems include wood (round cedar or pressure treated pine) or steel posts (galvanized or vinyl-bonded). The fabric can be vinyl-bonded chain link, netting or chicken wire.

Surface Basics :

- All Weather : A hard court surface, usually built with an asphalt base and an acrylic coating to provide color (and optional cushioning). These courts typically play faster and require little ongoing maintenance, but have a limited life span.

- Clay or Fast Dry : Clay is a natural product; fast dry is a crushed and blended green stone. Both play slow, are comfortable underfoot and allow slide, but require daily and seasonal maintenance. Properly cared for, they have an unlimited life span.

- Synthetic Turf : Created by weaving polypropylene synthetic grass fibers into a backing mat and held in place with finely graded sand. This surface is comfortable underfoot, and the level of sand determines the speed of play and foot-slide. Maintenance includes occasional sanding and brooming. Life span will depend on frequency of play; it wears as a carpet does.